Furniture importers and trucking companies are bracing for higher costs as new tariff actions raise expenses on a wide range of goods. According to recent reporting, companies that bring in furniture from overseas could face bigger customs bills, tighter margins, and schedule changes. Those pressures ripple across freight, warehousing, and retail. The key questions now are how much prices will rise, which items get delayed, and how brands adjust before the holiday season.

What’s changing and why it matters

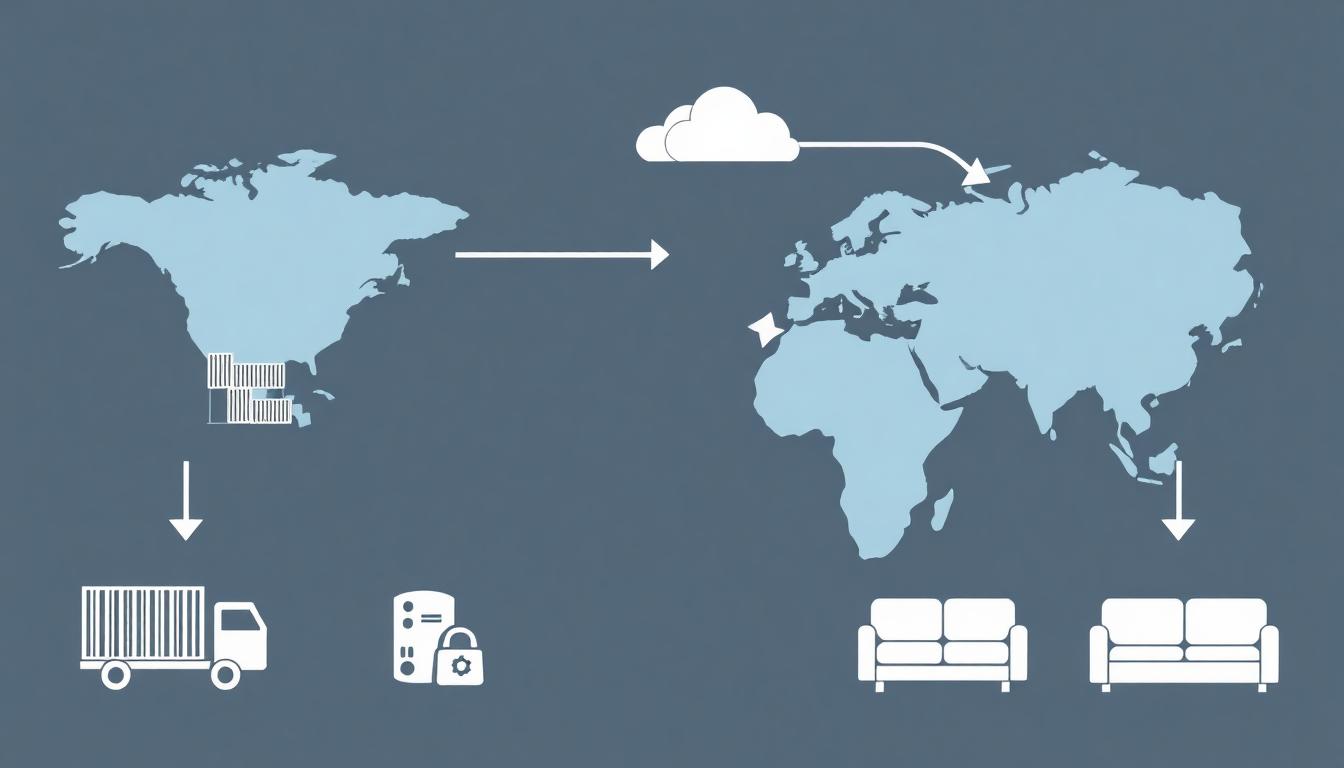

Tariffs are taxes on imported goods. When they rise, importers pay more at the border. Many furniture brands source products or components overseas, so added fees can be large. Trucking, drayage, and logistics providers also feel the effects, since tariffs can shift routing choices, container flows, and delivery timing. The result is a complex cost puzzle for retailers and a potential hit to consumers’ wallets.

Where the costs show up in the furniture pipeline

- At the port: Customs duties increase the landed cost of each container. Importers may split shipments or delay entries to manage cash flow.

- In warehousing: Higher carrying costs push companies to turn inventory faster; slow-moving SKUs face markdowns or cancellations.

- On the road: Drayage and linehaul plans shift as importers route to ports with better schedules or lower congestion.

- At retail: Price tags may rise first on bulky, high-freight items such as sofas, dining sets, and bedroom furniture.

Which products are most exposed

Bulky goods that fill containers quickly see the sharpest landed-cost impact. Upholstered sofas, sectionals, and wood dining sets are common examples. Flat-pack items can blunt some shipping costs, but tariffs still add to the base price. Any product with multi-country components, like fabric, foam, hardware, and wood, can see compounding fees.

How companies are responding

- Moving production: Some brands shift orders to alternative countries to lower duty rates.

- Adjusting assortments: Retailers emphasize best sellers and drop low-margin SKUs.

- Negotiating freight: Importers rebid drayage and trucking lanes; they tweak port choices and container mix.

- Pricing strategies: Companies test smaller, more frequent increases to avoid sticker shock.

Will shoppers pay more?

Likely yes, but not all at once. Retailers typically phase price changes. They may hold promotional prices on core sets to protect demand, while raising prices on premium or custom lines first. Expect more “limited-time” discounts that anchor higher list prices. Lead times for made-to-order pieces could also stretch if factories retool or shift sourcing.

What this means for small retailers and e-commerce sellers

Smaller players feel tariff shocks sooner. Cash flow gets tight when duties are due at entry. If you run a boutique furniture shop or a niche online store, consider these steps:

- Forecast demand weekly; update purchase orders in smaller lots.

- Use blended shipping: mix fast and slow lanes to hit priority dates without overspending.

- Promote in-stock items; highlight quick-ship assortments in ads and email.

- Bundle delivery and assembly; turn logistics into a value add, not a hidden fee.

Trucking and logistics implications

Tariff changes can scramble timing. Importers might hold containers at origin or choose different ports to manage duty exposure and inventory balance. That means trucking companies should expect:

- Short-term volume spikes as importers rush to beat date changes.

- Gaps afterward when shipments get delayed for rebooking.

- More appointment-based deliveries as warehouses run at tighter capacity.

How to talk to customers about pricing

Be clear and simple. Explain that freight, materials, and tariffs have raised base costs. Offer choices at multiple price points. Keep a few “hero” items as value anchors. Share realistic lead times and stick to them. Shoppers accept higher prices more easily when communication is honest and delivery is reliable.

What to watch next

- Official tariff timelines and any grace periods or exclusions.

- Factory lead times in key sourcing countries.

- Ocean spot rates and container availability in peak weeks.

- Retailer guidance on pricing and promotions ahead of holidays.

Tips for consumers

- Shop early if you need big pieces delivered by a specific date.

- Ask about in-stock alternatives to avoid delays.

- Compare total cost, including delivery and assembly.

- Look for floor model deals as retailers rebalance inventory.

Tariffs raise costs throughout the furniture supply chain. Importers, truckers, and retailers will adjust to keep goods moving, but some price increases and delays are likely. If you are a shopper, plan ahead. If you are a retailer, tighten forecasts, communicate clearly, and keep your best-value items front and center.

Sources and attribution

Primary reporting: CNN Business coverage on furniture, trucking, and tariff impacts. For official guidance on customs duties and classifications, see U.S. Customs and Border Protection. Industry commentary often comes from freight forwarders, trucking associations, and retail executives during earnings calls.

FAQ

Will all furniture prices go up?

Not all at once. Expect selective increases based on size, materials, and demand.

How fast will changes hit stores?

Some prices shift within weeks on new arrivals. Existing inventory sells at current tags until replenishment.

Can retailers avoid tariffs?

They can shift sourcing or apply for exclusions in some cases, but that takes time and planning.

To contact us click Here .